Auster

Wastewater Treatment Systems

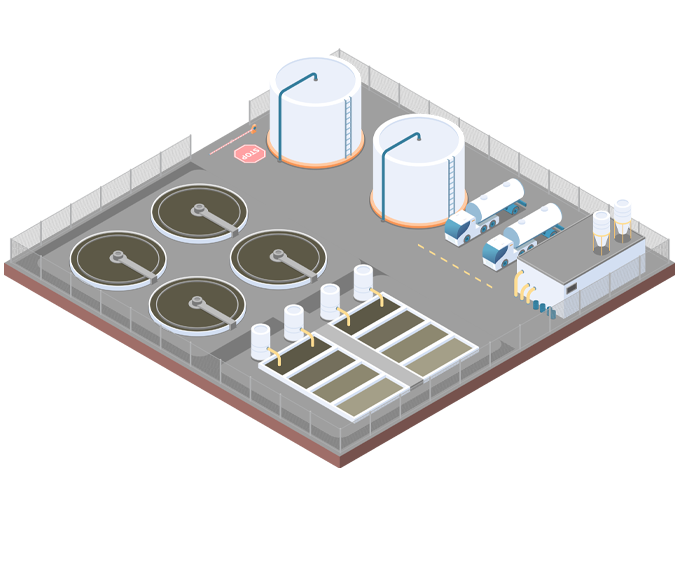

Industrial plants, factories, organized industrial zones are waste water treatment plants established for the purpose of recycling and disposal of waste water formed as a result of the production processes of such organizations.

These wastewater treatment plants are specially planned according to the character of the sector and wastewater. Waste water treatment systems designed for the treatment of industrial quality wastewater, sizes and treatment units vary according to industry/sector type, production method, amount of waste water, pollution values of waste water and type of receiving environment.

Why Auster Wastewater Systems?

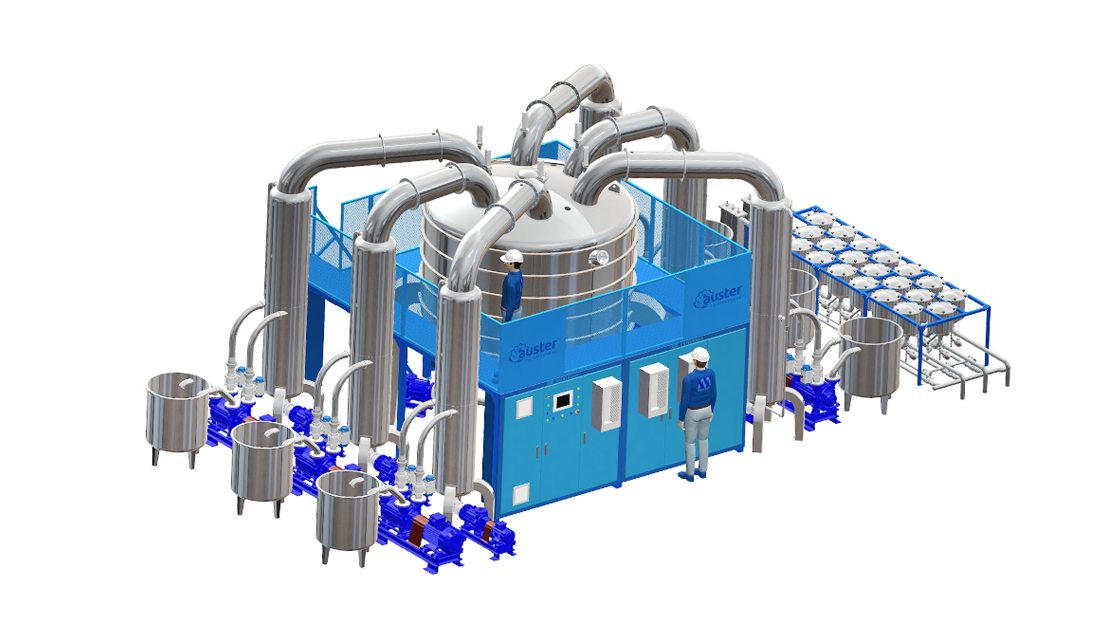

Univermak caustic recovery systems offer high efficiency with low energy consumption. The filtered wastes are taken into a vacuum jacket and packaged in a way that does not pollute the environment in any way.

High Productivity

Univermak caustic recovery systems, heating systems can operate between 1 - 6 bar steam pressure. There is a fully automatic cleaning system for tanks and filters.

No Environment Pollution

Wastes are , filtered with advanced filtration system and than packed with vacuum technology.

Low Energy Consumption

Univermak caustic recovery systems offer high efficiency with low energy consumption. Electricity Consumption=35kWh, Vapor Consumption = 300 Lt/hour

No Chemical

No chemicals are used at any stage of the process. Also, there is no need to clean soda with chemicals.

Energy Efficiency

As Univermak, we produce projects that minimize energy, water and maintenance and repair costs in our projects and provide maximum efficiency.

85

Energy Saving

Univermak provides an average of 85% energy savings, unlike the energy consumed in standard treatment facilities.

90

Saving on water

Univermak recycles an average of 90% of the water spent for production in enterprises to be reused in the enterprise.

75

Maintenance Savings

Our projects have a structure that works with a plug-and-play logic. This reduces your repair costs by 50%.

Sludge Disposal Difficulties

The biggest problem in standard treatment plants is the difficulty of drying and disposing the sludge. Since the humidity of waste sludge can not be decreased to the required level in sludge press or decantators, it is quite problematic to store high volumes of sludge and its delivery to disposal units.

AUSTER new generation treatment unit reduces the sludge humidity down to 2-3% and avoids flocking thanks to being checmial-free, so the waste sludge volume is 7 times less than normal waste sludge. The solid waste produced free of odor after sludge drying is stored and delivered to contracted facilities. Thus, companies will have less expenditures in removing the hazardous waste.

Sulphur and Odor Issue

There emerges a tense odor in standard treatment plants that caused by hydrogene sulphur and ammonia due to sludge produced during dephosphorization stage in nitrification and denitrification processes. Besides, hydrolically poor-designed treatment plants produce aerosol as a result of the wastewater flowing free, and dissolved gases are released. Heavy odor and unhygienic environment carries serious risks against the environment, workers in terms of workplace safety and health. For this reason, it is quite difficult for the industries to find employees to work at waste sludge sector. To avoid odor or to take it under control in such systems; use of odor sensors and perfume-supported deodorant chemicals is required, and the need of workforce is massive.

Since AUSTER new generation treatment unit is a covert-operating system, it prevents aerosol production and gas release from free-flow of wastewater during both the process and sludge drying stages. Its patented system “electro-disinfection” prevents the odor by removing odor-creating bacteria and gases.

Treatment Plant Erection Field

Standart treatment plants require balancing, airing and sludge sedimentation pools to be installed in a larger capacity when compared to that of the plant. Administrative buildings become complex systems by roofing a transformer building, blower and engine rooms for the motors.

AUSTER new generation treatment unit as a confined system on the other hand, can be installed in a small area of 50-100 sqms without needing an underground treatment pool (biological and sludge sedimentation). It is the only alternative solution developed against large treatment plants that occupy vast and valuable lands just like the ones in organized industrial zones and municipal/rural administrations.

Treatment Installation, Project and Design

Treatment-Related Maintenance Difficulties

Bacterial Management

Climate Conditions

In standard treatment plants, treatment is directly affected by varying climate conditions. When the water temperature in treatment pond is not between 10 – 25C, treatment process will lose its function and become totally inoperative. Water temperature specifically affects the nitrification process in a direct way. Low temperature; denitrification (nitrogen removal) process occurs below 10C depending on the ambient temperature. The operator can not manipulate such variations in water temperature but he can follow up and initiate back-up units if available.

High temperature; oxygen transfer will become harder over 25C and acquiring dissolved oxygen required by the biomass will be a problem. For this reason, necessary amount of biomass must be kept in airing pond. Besides, all the blowers in the facility must be maintained and kept operative before summer, and maximum number of blowers must be ready to operate when needed.

Changes in Wastewater Characteristics

in standard treatment systems, treatment capacity is planned in accordance with the KOI, PH and contamination burden of plant’s output waste. However, the varying daily processes in industrial plants cause such values in water to differ in a great deal. Wastewater with a heavy pollution load causes the averagely planned bacteria being unable to perform necessary fractionation, sometimes bacterial death or exceeding the waste discharge standards.

In AUSTER new generation treatment unit, being regardless of the plant’s waste values (unless the PH values do not dramatically diminish), treatment process continues without affecting the output water values.

Lack of Technical Stuff

Changing climate conditions in standard treatment plants, parameters subject to continuous follow-up, maintenance of the machinery all bring on a serious burden of work to both the management and the operators. Increasing levels of civil consciousness, welfare, communication and cultural aspects, causes an intolerance regarding the odor produced by treatment plants, and it falls back among employment choices of people.

AUSTER new generation treatment unit however, being a closed and compact system, malfunctions can be monitored through a control panel and repairs/maintenance can be implemented in a fast and cost-effective way.